Deca’s M-Series is a unique chips-first, face-up, fan-out wafer level packaging (FOWLP) technology that brings powerful benefits to a wide array of applications across the semiconductor industry.

With the fully encapsulated structure and a planarized build-up surface, M-Series is an ideal platform for single and multi-die packaging, high-density chiplet integration, 3D PoP, embedded bridge die interposers, and more. The 300mm wafer and 600mm large panel formats provide scalability and efficiency in manufacturing.

A Universe of Possibilities

Deca’s M-Series – Embark on a journey of limitless potential with M-Series… where a single technology opens the door to a universe of possibilities.

MCSP™

The fundamental building blocks of M-Series were first developed in the chip scale package (CSP) structure. This single die, face-up fan-in or fan-out wafer level packaging (FOWLP) technology includes Deca’s proprietary molded stress buffer layer which protects sensitive semiconductor device structures from package and board level stress while providing superior package-level and board-level reliability (BLR) performance as compared to conventional wafer level packaging (WLP).

M2CM™

M-Series multi-chip module (M2CM) expands upon the core technology to include multiple embedded devices. High-density interconnects between multiple devices are precisely optimized for the highest possible production yield with multi-mode Adaptive Patterning (AP).

MFIT™

M-Series Fanout Interposer Technology (FIT) is a powerful solution offering dual sided routing, dense 3D interconnects, and embedded bridge die for chips last heterogeneous integration of HBM, processors, and more.

MPoP™

A fan-out take on a classic PoP with 3D interconnects and dual-sided multi-layer routing. Our M-Series™ structure, materials, and design rules balance warpage, enabling a much thinner bottom package for memory mounting than competitors.

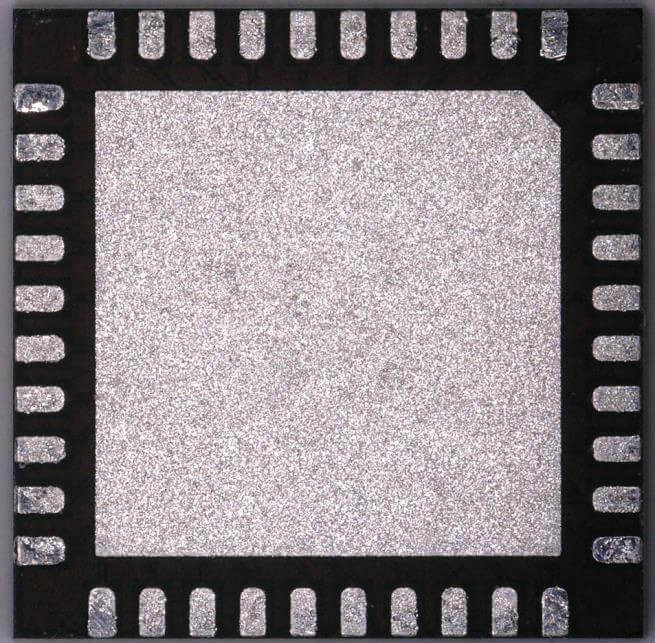

MDQFN™

A new take on the popular QFN (Quad Flat Pak – No lead) package using fan-out technology to eliminate the need for leadframes and provide a cost-effective solution. M-Series Direct (MD) QFN offers exciting new possibilities with unlimited design flexibility and powerful scaling roadmaps to higher interconnect densities and thinner package structures.

MDx™

Deca’s M-Series Direct (MDx) provides a groundbreaking extension to the industry-leading M-Series fan-out technology with elimination of capture pads on all fan-out build-up layers. Drawing inspiration from fab back-end-of-line (BEOL) processes, MDx integrates Deca’s existing advanced planarization techniques and proprietary Adaptive Patterning® to achieve the highest routing densities possible. MDx is currently being designed into a wide range of applications from 2.5D and 3D high-density chiplets to the revolutionary leadframe-free QFN structures of the future.